Our Popular Products

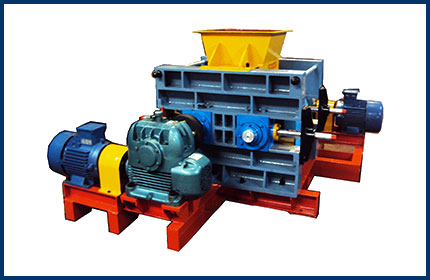

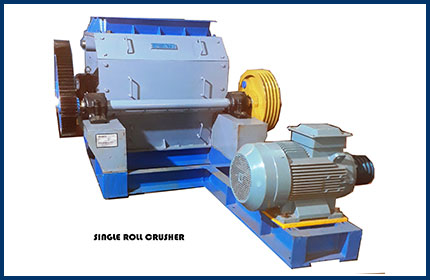

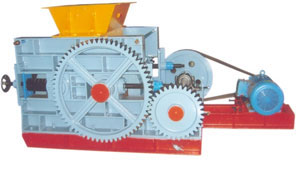

Friends Engineering Works, manufacture quality Roller Crusher for crushing any minerals. We manufacture different sizes and types of Roll Crusher.

We manufacture different type and sizes of Roll Crusher starting from Laboratory uses to Industrial uses. " FRIENDS" brand Roll Crusher suitable to crush Coal , Coke, Ore minerals, Ferrow Alloys, Clinker, Limestone, Ferro Manganese, Quartz, soft, hard and medium graded minerals etc.

To get maximum output yield, our Roller Crusher is suitable crushing machine, which users searching in the market . We give assurance to the users/ buyers of Roller Crusher, by which they may achieve higher performance. Our design is very sophisticated where power consumption is very low, annual maintenance is negligible, Wear and Tear of wearable parts is very low, high resisting capacity more than expected yield. Spare parts maintenance cost is very low. Foundation cost of machine is in capable range.

Body of Crusher fabricated from thick Mild Steel Plate ( as per specification) electrically welded with ribs, gasket etc. for rigidity of machine. Roller made from Mn. Steel casting ( IS 276, Gr III), Roller Shaft both driving and non driving made from EN Steel . Bearings SKF/ ZKL make fitted into own made heavy duty Bearing Housing , fitted with labyrinth seal Dust Cover. We provide all necessary accessories with the machine. Even it is painted as export quality supply.

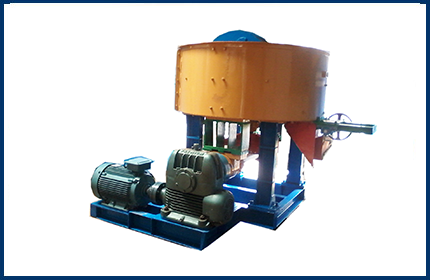

Friends Engineering Works , manufacture different type and sizes of Pulveriser for pulverizing Coal, Coke, Iron Ore, Manganese ore and any hard , soft, medium minerals. To get 100 mesh , 200 mesh, 300 mesh and 500 mesh , we insist the users to use our Pulveriser for Fine mesh Grinding Mill.

"Friends" THREE ROLL FINE MESH GRINDING MILL ( Raymond Type) is heavy duty for longer performance . Higher output achievement with minimum maintenance cost. Body of Fine mesh Grinding Mill fabricated from thick Mild Steel Plate, Roller, Bull Ring all are casted from cast Steel or Mn. Steel , (as required by users ). Complete Grinding Mill assembled with Body , Stand, Structure Frame Base Frame, Roller assemble, Dust collector, Air Classifier, Pipe Lines arrangement , Wizard Classifiers etc. Total machine driven by 3 Nos Motor.

NOTE: We manufacture only Single sizes of fine mesh Grinding Mill ( THREE ROLL GRINDING MILL ) for more fineness of required materials, where all fine mesh can be collected. Motor recommended 3 Nos ( i.e 01 No 30 HP 1440 RPM, O1 No 25 HP 960 RPM and 01 No 2 HP 960 RPM ).

Fine Mesh Pulveriser fabricated from thick Mild steel Plate. , MS Sheet , Cast Iron Base, Cast Steel or Mn. Steel Graded Hammer, Dust Collector, Air Classifier, Pipe line arrangement, Feed Hopper, Bag Filter and all necessary required accessories etc. Supply done after export quality painting and finishing.

"Friends" Pulveriser widely uses in the field of Crushing Coal , Coke, Ore minerals etc. Minimum power recommended by design section to drive the Pulveriser.

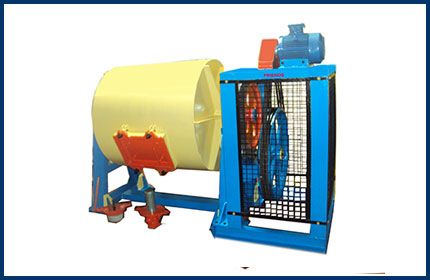

To get 100-200 mesh of any material, Ball Mill is suitable Grinding Machine from where users can get required materials output by Batch Type Grinding process. Ball Mill is widely used in laboratory process, testing sampling required by scientist, doctors, students and anybody else. Friends Engineering Works manufacture different sizes and type of Ball Mill. As per users requirement it can be lined by Sylex Brick lining, Porcelain Brick Lining, Canopy Bar Lining etc . See our table for requirement.

NOTE: Capacity depends on characteristics and abrasiveness of materials. Use of Grinding balls is also very important to get require output.

Friends Engineering Works manufacture Ball Mill ( Batch Type only) as per requirement of buyers. We design the Mill as per specification of users. The size may be changed/ modified as required by design. (Diameter and length of Mill may be changed when required. )

We fabricate the Mill from thick Mild Steel Plate electrically welded with Ribs and Gasket for rigidity of Mill. Supported Stand fabricated from heavy section ISMC welded with ISC.

All the materials are in graded quality. Journal Shaft duly machined as per Drawing and lathed 0-0 turning level. SKF/ ZKL make heavy section bearing fitted with Heavy duty Bearing Housing duly fitted with labyrinth Seal dust Cover. Ultimately Mill supplied in assembled condition and fitted with all required accessories etc. duly painted condition.

We also manufacture Laboratory uses Ball Mill , which is Ready to use model, where scientist or operator need not incorporate anything before install the Mill.

We also manufacture Stainless Steel fabricated Ball Mill.

Friends Engineering Works manufacture Heavy duty Swing Hammer Mill , Impactor, Hammer Crusher etc. All manufactured crusher body is robust fabricated from thick Mild steel Plate, Mn. Steel Liners . EN Steel fabricated Screen bars own made Cast Steel heavy duty bearing Housing Dust Cover and all necessary accessories etc.

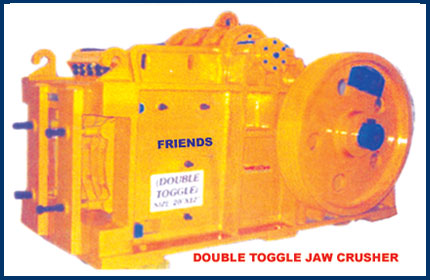

Friends Engineering Works manufacture and supplied lot of different sizes of Jaw Crusher for crushing coal , river Gravel, Stone, Feldspar, Lignite, Lime Stone, Quartz and all type of ore materials. We take responsibility to manufacture suitable Jaw Crusher as per required specifications of users . we manufacture Jaw Crusher for Laboratory and industrial uses both. For laboratory testing and analyzing purpose, those who related with any minerals testing Lab. Model. Jaw Crusher must be used for crushing and gradation of any useable minerals whose utility is vast for Industrial purpose. We design and manufacture Single Toggle and double Toggle JAW CRUSHER. Even our manufactured Jaw Crusher may be used to crush coal for Stroker Boiler. Friends Engineering Works manufacture different sizes of JAW CRUSHER , with application of minimum Power consumption and incurring negligible maintenance overhead. Following sizes are being manufactured by us.

NOTE: Capacity based on characteristics of material and also selection of Power Rating and how much moisture in crushable materials.

The body of Vibrating Screen manufactured by Friends Engineering Works is fabricated from thick Mild Steel Plate, electrically welded with supported Ribs and Stipner etc. EN Steel Forged Shaft is used as driving Shaft by eccentric driving rotation. SKF/ZKL make heavy duty spherical Roller or as per demand of design Taper Roller Bearing fitted with heavy duty Bearing Housing. We generally use High carbon Spring Steel Wire Net or perforated thick Mild Steel Plate as per Screening aperture.

NOTE: Capacity of Vibrating Screen depends on characteristics of raw materials and availability of moisture in raw materials.

We insist to install " FRIENDS" brand Vibrating Screen , to save your annual ,maintenance overhead expenses but yield of maximum gain.

Body of manufactured Muller Mixer , heavy duty, fabricated from heavy section ISMC, Flat and Angle , for rigidity . Base of Pan fabricated from thick Mild Steel Plate or Graded Cast Iron materials , duly finished by surface machining , then drilled and fitted with Extra Liner Plate for longer Performance and durability.

Muller Scrapper /Blade are made from ( IS276 Gr III) MN. Steel Casting or Stainless Steel Plate ( As per requirement of users). Crank Shaft, Bearing Housing , Driving Shaft all are forged from Graded Steel Casting. Maintenance , Greasing are very easy of " FRIENDS" brand Muller Mixer. The supply consisting all necessary accessories as per design.

NOTE: Capacity and Performance depends on characteristics of useable raw materials

For proper synchronize universal mixing cum blending , Double Cone Blender is suitable mixing machine. Generally it uses for dry processing mixing. But Friends Engineering Works manufacture both design either for Dry Mixing or wet mixing of any materials. But not for sticky materials mixing.

Friends Engineering Works manufacture of their Standard make Double Cone Blending Mill or Mixer of different sizes as per require capacity of users.

Body of Drum or Mill are fabricated ( as per design) from thick Mild Steel Plate electrically welded and fitted with two Nos conical/spherical shape cones with maintaining require degree for proper and synchronize mixing ( dry process).

No. of Steel fabricated Buffer or Blade fitted inside of Cone Mixer for proper Blending and mixing of grains exist in the materials.

Our standard make Double Cone Blender or Mixer to be supplied in assembled condition fitted with Motor, Gear Box etc. The Drive system arranged for V. Pulley , V Belt Drive or heavy duty Lovejoy/ Tyre Coupling coupled with Motor to Gear Box and with Drum Driving Shaft. Friends Engineering Works manufacture Double Cone Mixer or Blender as design is such type which is easy maintainable

Counter Current Pan Mixer is widely use in the Refractory Plant , for preparation of castable raw materials, tap hole Mass Preparation, any dry or wet mixing for Refractory and Monolythics plant where synchronize and universal homogeneous mixing is require, there Counter Current Mixer is an appropriate equipment.

The main and important mixing system is Rotating Pan of Counter Current Mixer is driven by individual Motor coupled to speed reduction Gear Box, designed for slow speed of Rotating Pan. Simultaneously Scrapper set with Arm of upper portion driven by same system but at comparatively higher speed.

And rotation of Pan and Scrapper rotates anticlockwise . as a special case it can be rotated at same direction.

Friends Engineering Works manufacture different sizes and different capacity of Counter Current Mixer , starting from 50 Kg to 500 Kg per batch . The design is heavy duty for longer better performance achievement .

Body of Mixer, Pan, fabricated from thick Mild Steel Plate electrically welded with supported Ribs and stipner etc.

Scrapper Set fabricated from thick EN Steel materials or as per requirement of design Mn. Steel or Stainless Steel Scrapper fabricated. All the Scrappers are fitted with heavy duty Arm arrangement , which assembled with upper body of Mixer and driven by separate Drive System.

Design of Counter Current Mixer by Friends Engineering Works is such that where Pan Cover is fitted with upper drive frame. At the time of discharging materials upper drive with Pan Cover can be lifted manually or hydraulic arrangement system as required. Sometime in case of small quantity mixing, pan can be lifted by manually for collection of mixing materials.

Our design is acceptable everywhere, as total operating time takes 15- 20 minutes ( mixing and discharging both ). Easy maintenance system and maintenance cost is very negligible.

Power Consumption ( Motor 02 Nos ) is in bearable range of users.

Please note capacity , wear and tear and maintenance expenses depends on characteristics of useable raw materials .